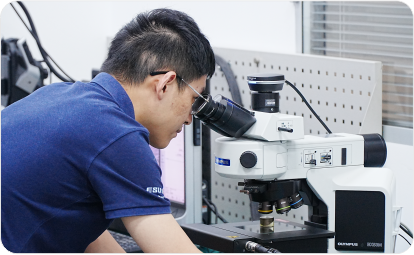

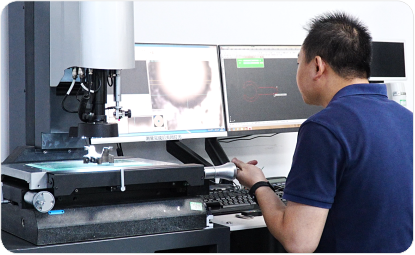

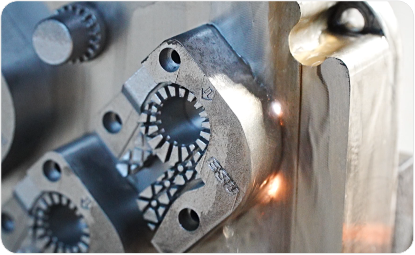

Accelerating the world's transition to additive manufacturing

Industry leader, World-class

Everyone has literacy, ESU has soul

Dedication, Gratitude,

Cooperation, Progress

北京大學光華管理學EMBA

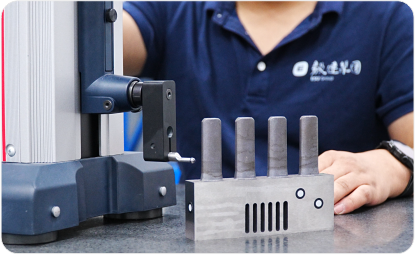

2004年創立上海占瑞模具設備有限公司,深耕模塑行業20余年

2013年,聯合創建“長富銀基金管理(北京)有限公司”,并擔任董事長

2016年,榮獲金磚傳媒頒發的“金融騎士獎

北京大學光華管理學EMBA

2018年整合上海毅速激光科技有限公司,進入金屬增材制造行業多年的企業管理實踐經驗,提升了戰略規劃能力和較強的凝聚力,對品牌運營和市場營銷有較深的理解,企業管理中注重創新和企業文化的打造

曾擔任上海河南商會的中務副會長,北京大學光華管理學院華東校友會副會長